Laser cutting gaskets has revolutionized the industrial sealing landscape by offering unprecedented precision and versatility. Traditional die-cutting methods have inherent limitations in achieving complex geometries and maintaining tight tolerances. In contrast, laser technology enables manufacturers to create intricate designs with tolerances as tight as ±0.05mm. This level of precision is critical for high-pressure applications where even minor imperfections can lead to catastrophic system failures.

The non-contact nature of laser cutting eliminates the tool wear issues associated with conventional methods. This results in consistent quality across production runs regardless of volume. For industries dealing with hazardous materials or extreme operating conditions, this consistency translates directly to enhanced safety protocols and extended equipment lifespan.

Custom Engineering for Critical Applications

The ability to rapidly prototype and produce custom gaskets has transformed how engineers approach sealing challenges in specialized equipment. Industries such as pharmaceutical manufacturing, aerospace, and chemical processing benefit tremendously from tailored solutions that address unique operational parameters.

A steam valve gasket designed for high-temperature steam applications can now be precision-engineered to account for thermal expansion, chemical compatibility, and pressure fluctuations specific to the exact valve model. This customization extends beyond simple dimensional accuracy to include specialized edge treatments and variable thickness profiles that were previously impossible to achieve consistently.

For facilities running proprietary equipment or legacy systems, laser cutting gaskets offers a viable alternative to costly equipment replacement by creating perfect-fit replacement parts that meet or exceed OEM specifications.

Advancing Steam Valve Gasket Performance

The performance demands placed on a steam valve gasket continue to increase as industrial processes push toward higher efficiency and more extreme operating conditions. Modern steam systems frequently operate at temperatures exceeding 1000°F and pressures above 4500 psi, creating sealing challenges that conventional gaskets struggle to address.

Laser cutting technology allows for the precise implementation of anti-blowout features and controlled compression zones within steam valve gaskets. These design innovations significantly reduce maintenance frequency and unplanned downtime. By incorporating microscopic surface textures that enhance sealing properties, laser-cut steam valve gaskets achieve superior performance even under fluctuating pressure conditions.

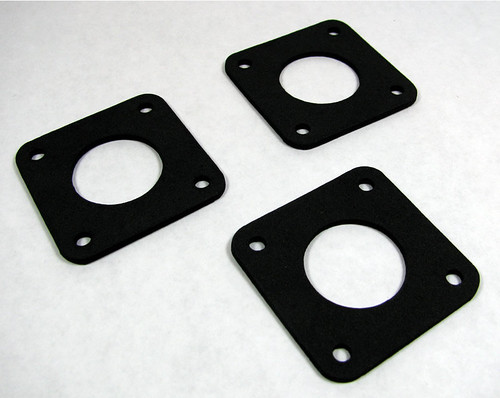

The ability to create perfectly matched bolt hole patterns eliminates installation errors that commonly lead to premature gasket failure. This precision ensures even compression loading across the entire sealing surface, a critical factor in steam containment applications.

The Evolution of Corrugated Gasket Technology

Corrugated gasket designs have long been valued for their resilience under thermal cycling conditions. Laser cutting has taken this established technology to new performance levels by enabling precise control over corrugation patterns, depths, and spacing. This control allows engineers to optimize gasket recovery properties for specific application requirements.

Modern corrugated gasket variants incorporate asymmetrical patterns that were previously impractical to manufacture. These innovations distribute compression forces more effectively, particularly in flange connections subject to vibration or thermal expansion. For applications in extreme temperature environments, a precisely laser-cut corrugated gasket provides superior recovery characteristics compared to traditional flat gaskets.

The material integrity preserved during laser cutting means that corrugated gaskets maintain their designed recovery properties throughout their service life. This preservation of elastic properties translates directly to extended maintenance intervals and reduced leakage incidents.

Material Innovations in Gasket Manufacturing

The precision of laser cutting gaskets has driven parallel innovations in gasket materials. Manufacturers now develop specialized composites specifically designed to leverage the advantages of laser processing. These materials combine the thermal stability of ceramic fibers with the resilience of high-performance polymers, creating gaskets that excel in extreme service conditions.

Advanced graphite composites, when laser-cut, maintain their integrity at the microscopic level, eliminating the edge fraying common with mechanical cutting methods. This edge quality preservation is particularly important for steam valve gasket applications where degradation often begins at material boundaries.

Multi-layer composite materials benefit tremendously from laser cutting precision, allowing engineers to design gaskets with different performance characteristics across various sections. This innovation enables a single corrugated gasket to provide both excellent sealing in static areas and superior recovery in dynamic zones.

Quality Assurance in Precision-Cut Gaskets

The digital nature of laser cutting gaskets technology integrates seamlessly with modern quality assurance protocols. Each gasket can be automatically inspected and verified against design specifications with optical recognition systems. This integration enables 100% quality verification rather than statistical sampling, dramatically reducing the risk of defective parts entering service.

For critical applications such as high-pressure steam valve gasket installations, this quality assurance creates documented traceability from raw material to installed component. Regulatory compliance in industries such as power generation and chemical processing demands this level of documentation, making laser-cut gaskets particularly valuable in these sectors.

Advanced manufacturers now implement real-time monitoring during the laser cutting process, adjusting parameters instantly to account for minute material variations. This adaptive manufacturing approach ensures consistent quality even when processing challenging materials like compressed fiber composites or PTFE-based sheet goods.

Cost-Efficiency and Sustainability Benefits

Despite the advanced technology involved, laser cutting gaskets often delivers cost advantages over traditional manufacturing methods. The reduction in tooling costs makes small production runs economically viable, eliminating the need for large inventory holdings of specialized gaskets. For maintenance departments, the ability to quickly produce exact replacements for a failed steam valve gasket or corrugated gasket significantly reduces expensive downtime.

Material utilization improves dramatically with optimized nesting algorithms that maximize yield from raw sheet stock. This efficiency reduces waste while lowering per-unit costs. Additionally, the precision of laser cutting extends gasket service life, reducing the total lifecycle cost of sealing solutions in critical applications.

Environmental benefits extend beyond material efficiency. The elimination of lubricants and coolants required in traditional die-cutting processes creates a cleaner manufacturing environment and reduces hazardous waste disposal requirements. For organizations pursuing sustainability initiatives, these advantages align perfectly with environmental responsibility goals while simultaneously improving operational efficiency.